Steam Condensate Cooling Tank

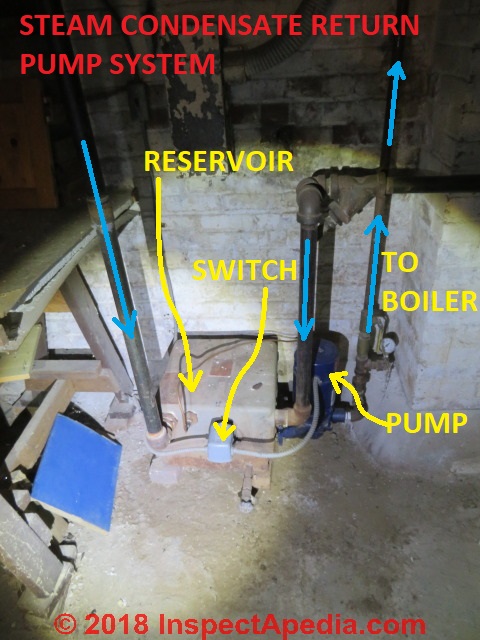

Remember steam heating applications using thermostatic traps drain condensate around 160 to 180 degrees.

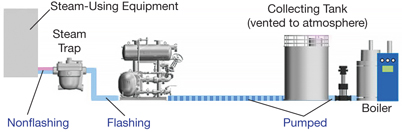

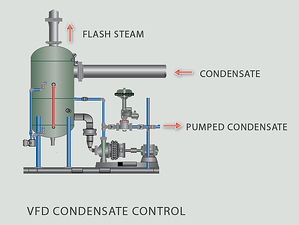

Steam condensate cooling tank. The condensate receiver should not be used as a flash tank. If the steam trap is of a thermostatic type the discharged condensate is sub cooled below saturation temperature. Our flash tanks are designed to separate the steam from high pressure condensate. Pressure at source steam traps or blowdown valves volume of condensate to be cooled pressure and temperature of cooling water high temperature limit of waste condensate normal sizing by condensate load cc 6 up to 2 000 lbs hr.

Asme flash and condensate tanks flashing occurs when hot water at a higher pressure is suddenly released to a lower pressure. Condensate greater than 180 f option a flash tank vent option b condensate cooler hot condensate 1 minimum air gap required to eliminate back siphonage a w h b c d cold water vent hot condensate tempered. The 3450 rpm motors assure maximum efficiency and an economical operation. Thick tank wall design and wear resistant pump seals for a longer run time.

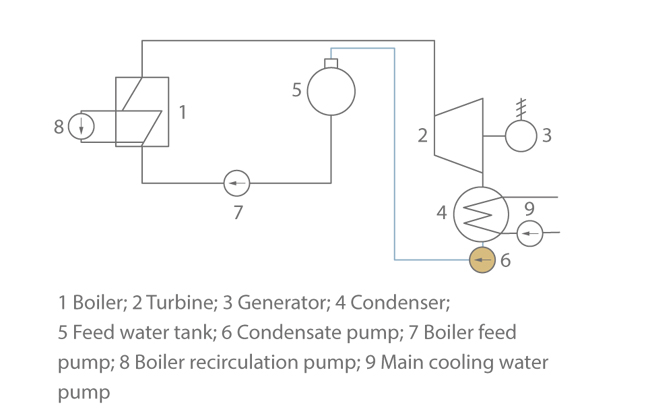

Condensate should be flashed prior to entering the condensate cooler. When hot condensate or hot water is drained into the condensate cooler body the tempering valve opens and allows cold water to enter the chamber and mix with hotter liquid cooling it to a preset temperature level of 135 f 57 c or to a desired field set temperature. The condensate tanks routinely have extremely high process temperatures so a level measurement and point level detection are necessary that can withstand this environment. Most pumped condensate return units operate from a vented tank.

Flash tanks provide a common lower pressure point for collecting condensatre a means to cool hot condensate and a source of low pressure steam for heating or process use. Cc 12 up to 10 000 lbs hr. Sterlco condensate units set a new standard of performance for pumping condensate water in a steam system. To avoid waterlogging the steam main the use of a generous collecting pocket on the main plus a cooling leg of 2 to 3 m of unlagged pipe to the trap is essential.

It is a pre assembled package that is suitable for any plumbing system. This condensate accumulates from the steam system that is used to heat the various hydrocarbon processes. View all condensate units thicker tank wall design and wear resistant pump seals keep the system running longer and require less maintenance. Cc 16 up to 20 000 lbs hr.

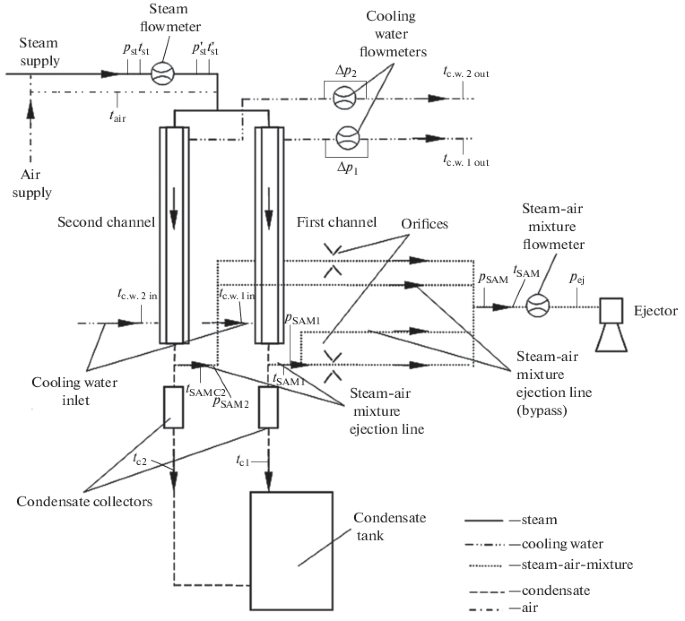

Sterlco steam control products for top performance in your operation choose the proven accuracy of the sterlco full line of steam control products. The example shown in figure 14 6 1 is depicted in figure 14 6 2 and shows that 0 134 kg of flash steam is produced per kg of condensate passing through the trap. At 180 degrees a condensate pump mounted to a collection tank at the same level as the pump will have about 15 feet of npsha in the water.