Turbine Lube Oil Cooling System

3 provide oil to turning gearing device.

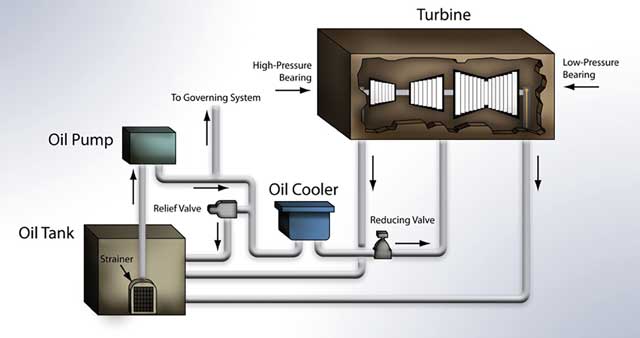

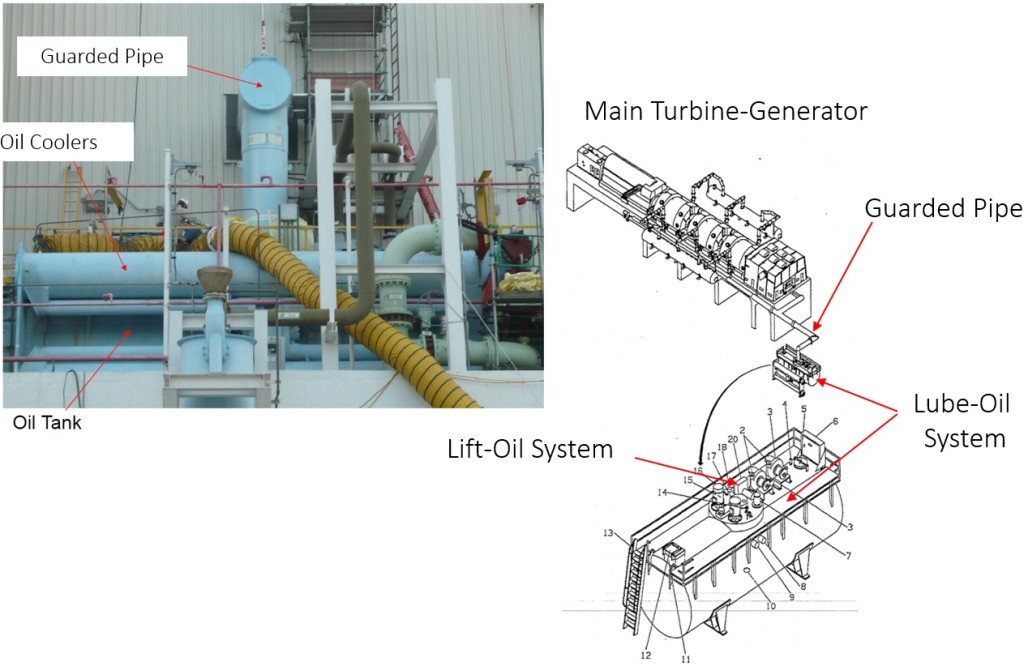

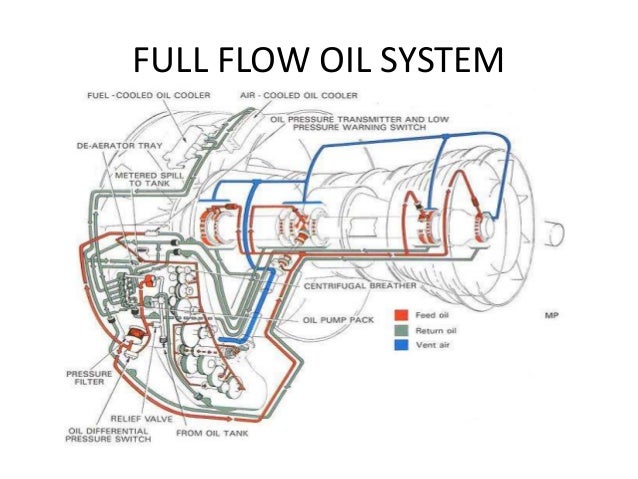

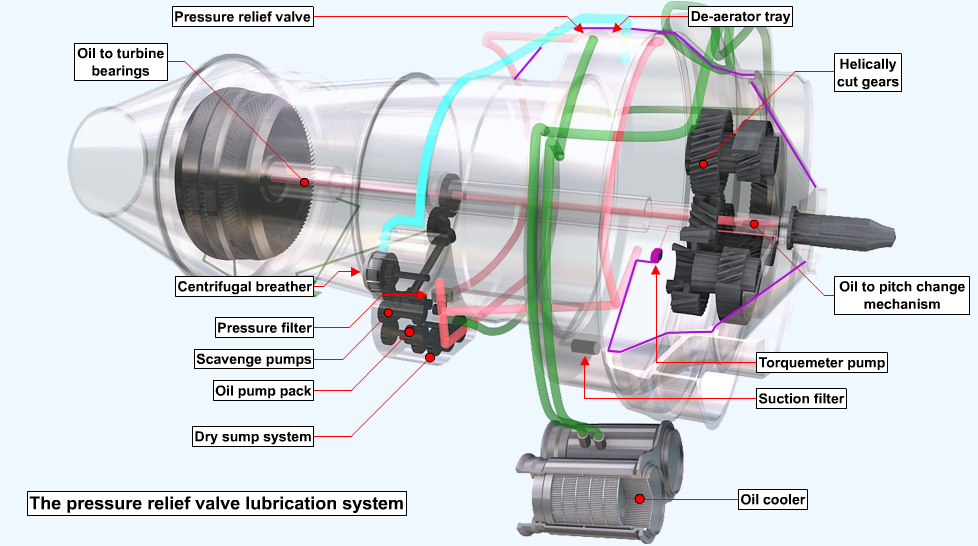

Turbine lube oil cooling system. 2 provide lubrication oil to all bearing shafts of the unit and cooling meanwhile. Efficient turbine lube oil cooling is critical to the reliability of turbine generator or turbine driven compressor applications. Turbine oil supply system function. Lube oil systems provide lubrication and cooling to gas turbines and other industrial equipment.

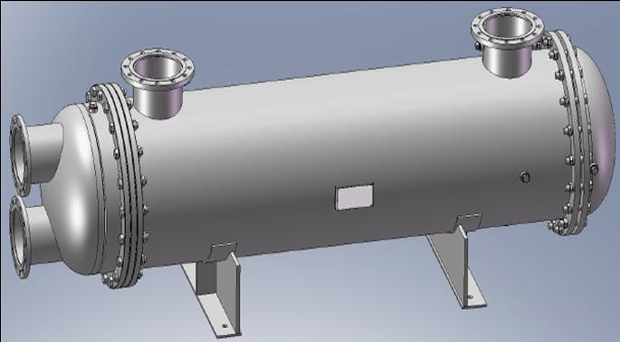

The definition of turbine oil is. To keep the lube oil at the right temperature and the right viscosity for safe and reliable operation alfa laval offers an extensive range of coolers and cooling skid systems from off the shelf systems to custom engineered heat exchangers. Turbine lubricants must control the rust and corrosion that could destroy precision surfaces resist foaming and air entrainment which could impair lubrication. The system assists in dissipating or settling contaminants providing for temperature fluctuations and storing oil.

Reciprocating engines like gas turbines run at efficiencies near 30. Turbine oil is commonly referred to as turbine oil including gas turbine oil steam turbine oil etc which are commonly used in the reduction gears sliding bearings and hydraulic control systems of the connected units. Approximately 48 of the waste heat is in the exhaust stream 27 removed by the lube oil system and 25 removed by the jacket cooling system. 1 provide pressure oil to conditioning system and protection devices.

Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100oc in typical steam turbine or industrial heavy duty gas turbine and exceed 200oc in aero derivative gas turbines. In a full scale application allegheny energy collaborated with aggreko to provide temporary supplemental lube oil cooling for the no. In turbomachinery they are important for hydrodynamic bearing performance. Friction and the heat from combustion increase the oil temperature reducing its viscosity.

Temperature control system all engines use oil as a lubricant to seal the compression chamber and reduce piston wear and friction. However their waste energy is split between the exhaust lube oil system and jacket cooling system. The main functions of turbine oil are cooling speed regulation and lubrication. The importance of the turbine lube oil cooler is maintaining optimum oil temp of the turbine lube oil and if this exchanger experiences leaks it can result in contamination of the lube oil or release of turbine lube oil into the environment.