Underground Cable Laying Machine Name

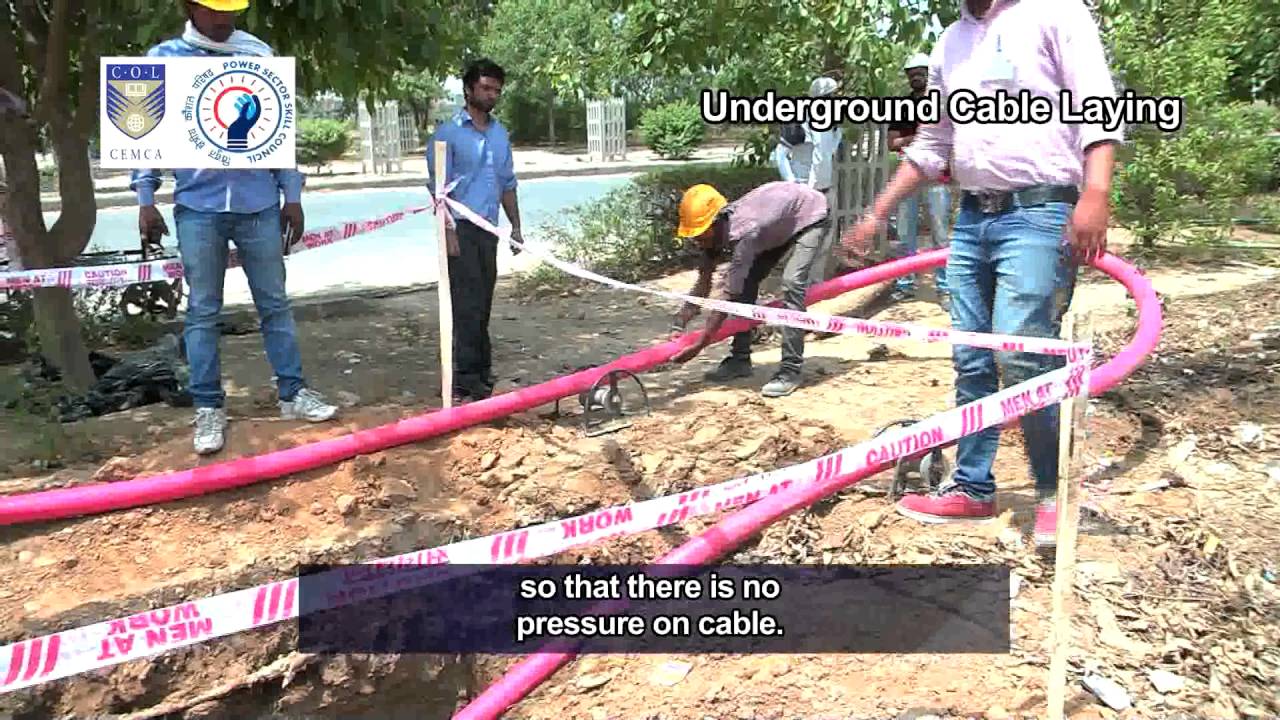

This video presents the fiber optic cable laying on underground application.

Underground cable laying machine name. Directional boring also referred to as horizontal directional drilling hdd is a minimal impact trenchless method of installing underground utilities such as pipe conduit or cables in a relatively shallow arc or radius along a prescribed underground path using a surface launched drilling rig. These three methods are explained below with their advantages and. Underground cable laying underground cabling providers in india. The testing repairing and certification service of this machine is provided to our clients with the support of our skilled professionals.

Laying uf underground feeder cable directly into the ground this is known as direct burial and if you do this the uf cable must be at least 24 inches below the surface of the ground to minimize the chance of the cable being pierced by routine shoveling. Hands on video training presentation for osp fttx project deployment and activ. Further the vertical runs where the cable descends into the ground at the house side and emerges up from the ground at the outbuilding. Machinery and equipment for underground cable laying.

Since 1972 line ward has hand crafted the highest quality line layers and boring equipment specifically designed for seamless underground cable and pipe line installations. Directional boring hdd offers significant environmental advantages over traditional cut and cover. The reliability of underground cable network highly depends upon proper laying of cables quality of cable joints and branch connections etc. We render these services at market.

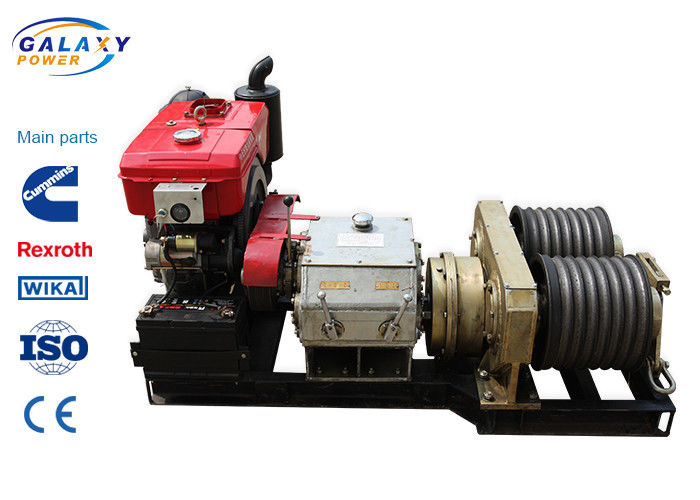

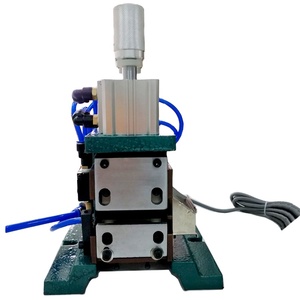

The cable pusher is widely used in underground big power cable pulling project. We can use 6 8 machines for big power cable pulling project. Get contact details and address of underground cable laying underground cabling firms and companies. This method of laying underground cables is simple and cheap and is much favoured in modern practice in this method of laying underground cables a trench of about 1 5 metres deep and 45 cm wide is dug the trench is covered with a layer of fine sand of about 10 cm thickness and the cable is laid over this sand bed the sand prevents the entry of moisture from the ground and.

Omac manufactures machines for laying underground cables and related equipment. The range of machines manufactured by omac covers all types of hydraulic pullers specifically designed for laying low medium high voltage underground cables fiber optic and for pipes renewal.