Vertical Cooling Tower Pumps

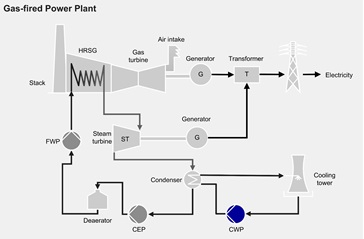

Cooling water pumps cwp provide the fresh water to cool the exhaust steam in the condenser and pump it back to the wet cooling tower or the outlet of open cooling system.

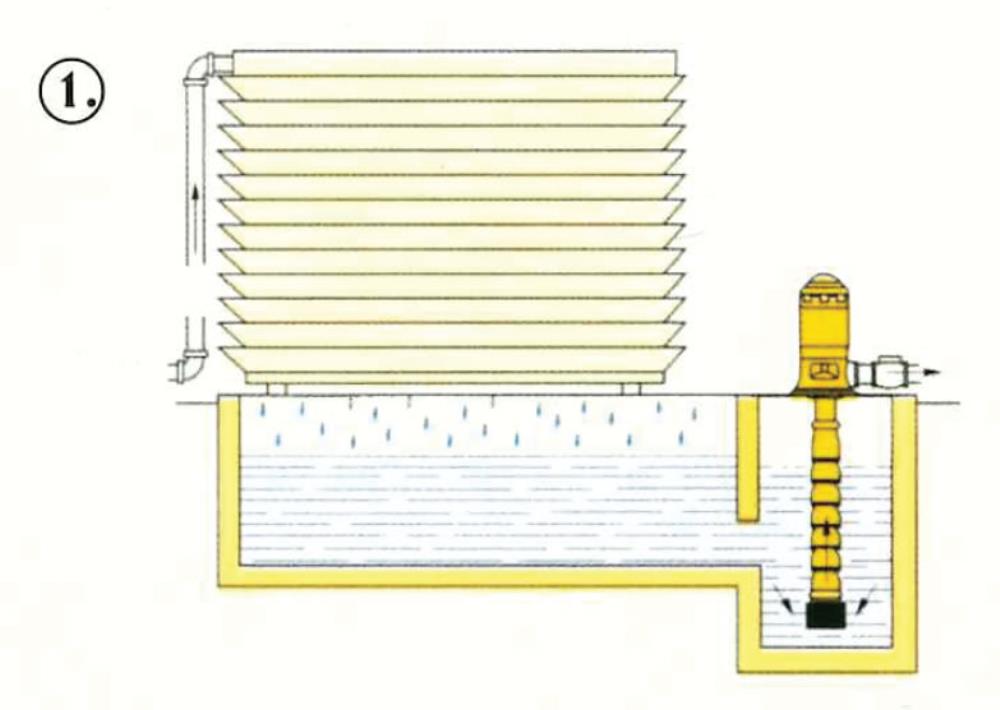

Vertical cooling tower pumps. It must also provide the energy head necessary to raise water from a low to a higher static head level. In medium to large size gas fired combined cycle power plants the cwp are vertical column type. Grundfos offers pumps controlled by constant discharge temperature and fan motors controlled by the. Smart pumps are also designed to help reduce operating and maintenance costs.

Their flow rate varies depending on the heat flow to be dissipated. The vl vls inline pumps have proven to be extremely versatile often exceeding the requirements for a variety of market applications such as chilled water condenser water and hot water systems. Hospitals require an ambient temperature of 72o 24 7. Industrial makeup water cooling tower applications and fire pumps.

They are often operated with both shower nozzles and fans running at full capacity meaning energy waste due to not adapting to the specific load. Cooling water pumps are used for supplying heat exchangers with cooling water. 2 3 cooling towers in healthcare cooling is especially important in hospitals and medical centers. Range of head and flow rate the required heads for fresh water operation usually lie within 5 to 15 m.

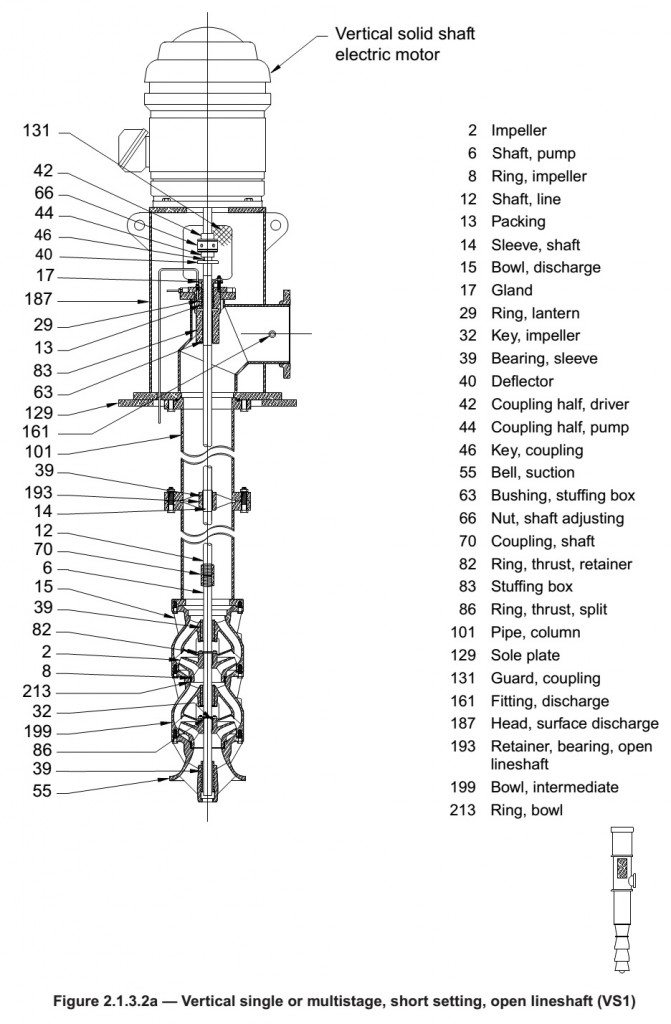

They comply either with iso asme or api standards and guarantee reliable and efficient processes. The major characteristic of the cwp is their high flow. This is of special concern with variable speed large multistage horizontal and or vertical pumps. A margin of safety should be provided between the pump vane pass speed frequencies and major structural and or pipe hydraulic natural frequencies.

The pumps are usually horizontal end suction split case double suction or vertical turbine pumps. Numerous sizes hydraulics and material combinations are particularly well suited for use in applications where uncompromising reliability and. Piping condenser cooling tower losses and valves. The amplitude of the vibration response can be amplified 2.

A distinction is made between wet cooling and dry cooling processes. The required head is determined by the type of cooling system. Vertical turbines are commonly used in all types of applications from moving process water in industrial plants to providing flow for cooling towers at power plants from pumping raw water for irrigation to boosting water pressure in municipal pumping systems and for virtually every other imaginable pumping application. Typical acceptable margins are 15 25.